Leveraging AI for Predictive Maintenance in Manufacturing

Today’s manufacturing processes rely on a complex network of machinery. From CNCs to assembly line robotics, these systems are the lifeblood of manufacturing – and they need to run reliably. Studies show that unplanned downtime can regularly cost $125,000 per hour, and sometimes as much as $2 million per hour.

Needless to say, anything that prevents machines from experiencing downtime is a highly valuable resource. Predictive maintenance, governed by AI, might just be that resource. Artificial Intelligence (AI) is the key enabler of next-gen predictive maintenance. Let’s explore why it’s a game changer, and how businesses are already leveraging it.

What is Predictive Maintenance?

Predictive Maintenance (PdM) uses real-time data to monitor machines and anticipate equipment failures before they happen. Rather than answering the question “Has this machine failed?” or even “Will this machine fail?” PdM seeks to answer the question “When will this machine fail?”

PdM is different from reactive and preventative maintenance in that it responds to real-time data, rather than an incident, and requires no regular scheduling.

- Reactive Maintenance: Fix the problem after it happens

- Preventative Maintenance: Schedule maintenance at regular intervals

- Predictive Maintenance: Anticipate problems and fix them before they happen

Why AI is a Game-Changer in Predictive Maintenance

While it’s possible to do predictive maintenance without AI (through threshold monitoring, trend analysis, and statistical modeling) it is much less accurate and powerful. It’s also more labor intensive, making it costly.

AI is able to take in and analyze massive amounts of data, uncovering patterns humans may miss. Here are a few things AI in manufacturing enables that are harder to achieve with human intervention alone.

-

Anomaly Detection

AI identifies deviations from normal performance more quickly than humans can, meaning the likelihood that it will intervene before a problem occurs is higher.

-

Failure Prediction

Machine learning models forecast which parts are likely to fail and when. This allows manufacturers to fix only what’s needed, only when it’s needed.

-

Root Cause Analysis

AI systems can pinpoint underlying factors, not just symptoms, meaning that analysis of the root cause can be done before failure, not just after.

-

Prescriptive Insights

Advanced AI not only predicts failure but suggests optimal maintenance actions.

With AI-powered prediction, manufacturers experience lower maintenance costs, increased uptime, and improvements in asset utilization and lifespan.

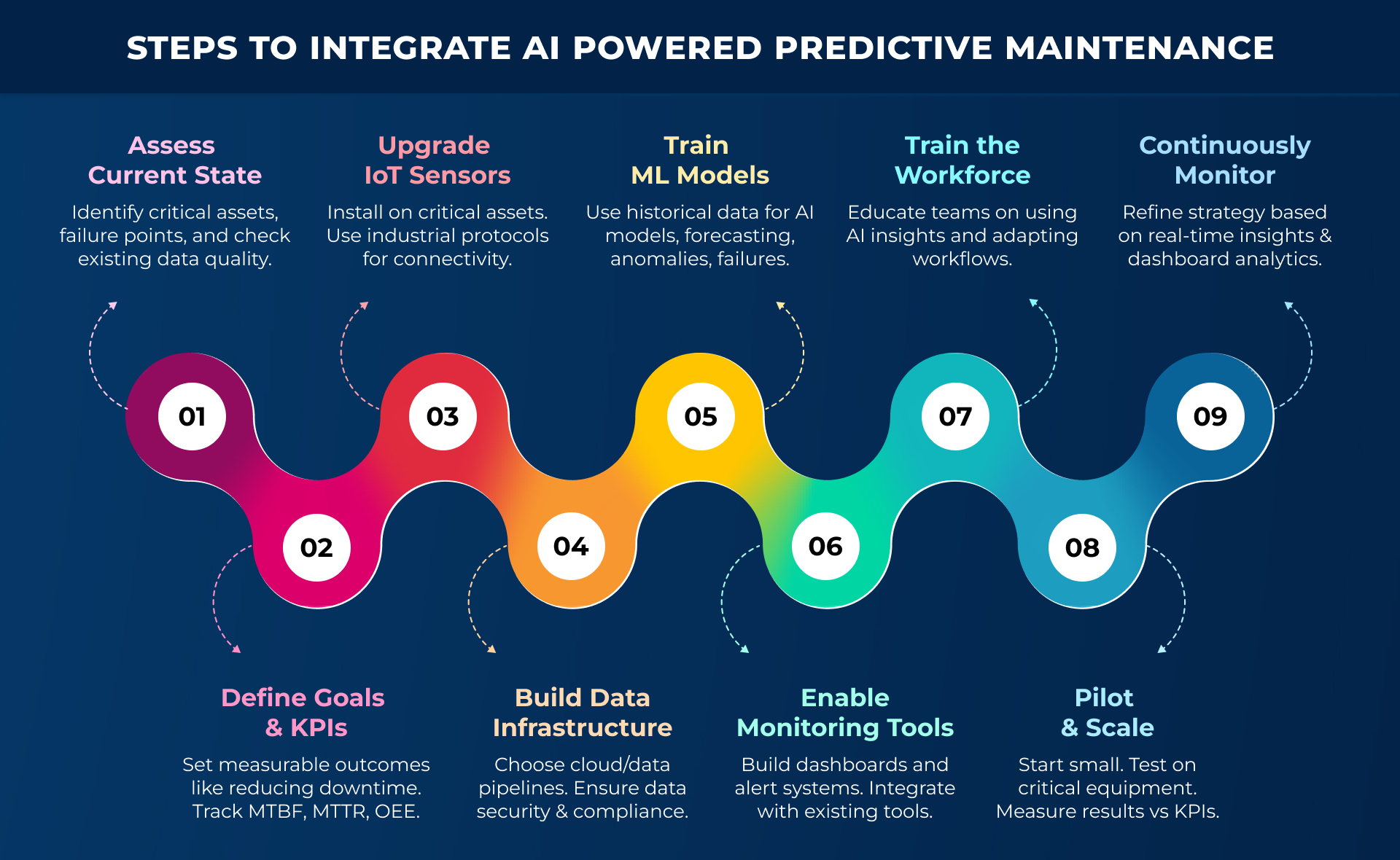

Steps to Integrate AI Powered Predictive Maintenance in Manufacturing

The process of integrating AI-powered PdM into your manufacturing isn’t easy, but it can be done with some up-front planning and careful forethought. Here’s a brief but clear overview of the steps you’ll need to take to get AI-driven PdM into your manufacturing operations.

1. Assess current maintenance and data landscape

You’ll need a clear overview of your current machines and failure points. Identify critical assets that most impact production. Evaluate your current sensors and data quality.

2. Define objectives and KPIs

Set clear goals like “reduce downtime by X% in X timeframe.” Define KPIs such as Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), and overall equipment effectiveness (OEE).

3. Install or upgrade IoT sensors

If any new sensors are needed, install and configure them. Test to ensure proper functionality. Deploy on critical equipment first. Use industrial protocols like MQTT, OPC-UA for seamless integration.

4. Set up data infrastructure

Decide on a storage solution and upgrade to cloud platforms if need be. Implement pipelines for ingestion, cleaning and normalization. Ensure security and regulatory compliance.

5. Develop or adopt ML models

Use your existing data to train predictive models. Historical failure data and sensor data will help you employ machine learning techniques: anomaly detection, regression, classification, and time-series forecasting.

6. Implement monitoring tools

Create dashboards for asset monitoring and crash visualization. Set thresholds and integrate with existing systems.

7. Train workforce

Perhaps the most important step to foster an environment of collaboration and excitement. Provide training sessions on interpreting AI insights and new maintenance workflows and encourage collaboration.

8. Pilot and scale

Start with a small program on just your most critical machinery. Measure the impact against your KPIs and existing processes.

9. Monitor

Regularly monitor your dashboards and sensors for updates and changes or issues. Use the insights your gather for strategic asset management or investment planning.

Core Technologies Behind AI-Driven Predictive Maintenance

AI-driven PdM relies on a few crucial components and technologies.

-

IoT Sensors & Edge Devices

Temperature, pressure, moisture, vibration, electric current and various other types of sensors collect data from machines as they run. GE’s Predix platform uses IoT sensors installed on turbines to continuously stream data, for example.

-

Cloud Computing / Data Storage

The data collected by IoT sensors and edge devices must be stored so they can be analyzed. Many companies rely on services like AWS to centralize manufacturing data.

-

Analytics

Big data analytics platforms like AWS and IBM Maximo perform efficient data analysis across massive fleets of equipment to detect anomalies.

-

Machine Learning Algorithms

Predictive models forecast failures and also learn from past failure to create robust detection systems. SparkCognition, for example, uses deep learning to predict failures in oil & gas equipment with high accuracy.

-

Automation & Orchestration Tools

Triggering workflows for alerts is a key step in the PdM process. Integration with something like ServiceNow or SAP helps automate work orders based on AI predictions.

Real-World Applications and Use Cases

Companies are already deploying AI-assisted predictive maintenance systems to help them prevent and detect anomalies. Here are a couple of examples of how BMW, Toyota, GE, and Shell are leveraging this powerful tool in manufacturing technology.

-

BMW & Toyota: Preventing Robot Arm Failures in Automotive Engineering

These companies use IoT predictive analytics to monitor vibration and torque in robotic arms and detect early signs of mechanical degradation or motor overheating. This has led to reduced unplanned production line stoppages and improved robotic cell uptime.

-

GE Aviation: Improving Jet Engine Health Monitoring

Jet engines are equipped with hundreds of sensors to monitor temperature, pressure, vibration, and fuel efficiency. In this way, GE uses AI to predict component wear, allowing airlines to schedule maintenance between flights and avoid failures mid-flight.

-

Shell: Monitoring Pipelines and Compressors in Oil & Gas

Shell uses AI models to analyze acoustic and vibration data, allowing them to detect corrosion, pressure leaks, or compressor fatigue. This has prevented pipeline ruptures, reduced emergency interventions, and optimized maintenance cycles.

Conclusion

Using machine learning for equipment monitoring is a powerful way to leverage future-proof technology to improve your bottom line. But it can feel overwhelming to navigate the complexities of manufacturing software development. That’s why a trusted partner like Telliant is critical for your success. Our experienced teams can help you strategize and implement your shift to PdM smoothly.

Contact us today to learn more.